| |

|

|

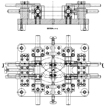

Design department of PMS Engineers is well equipped with softwares which include Solid Works 2010; a 3D CAD software and DelCAM for CNC tool path generation.

We design the fixtures taking into consideration; optimum utilization of available Space and Materials, Ergonomics, Fool Proofing, Swarf Removal, Line Balancing, Ease Of Loading and Unloading and Ensuring Inbuilt Quality.

Over last 19 years “PMS ENGINEERS” has manufactured various types of Drilling jigs which include indexing jigs ranging from 100 mm Ř to 1500 mm Ř for conventional machines. Fixtures include holding fixtures for conventional milling as well as HMC & VMC machines for components like Cylinder Heads, Crank Shafts, Connecting Rods, Gear Casings, Flywheel Housings & various types of Air Inlet & Exhaust Manifolds. PMS has also manufactured Welding Fixtures for Rear & Front Axles which covered components up to 3500 mm in Length.

Recent endeavor of PMS includes manufacturing of “Line Boring Fixture” for ‘Diesel Engine Crankcase’. This fixture was 1800 mm in length which was aligned within 5 microns for Precision Boring.

|

| |

|

|

|

|

|

|

|

|

At PMS Engineers we design and manufacture precision acceptance gauges or functional gauges. The main purpose of these gauges is to check the fitment of the component in assembly as well as the functional requirement of the component. In mass scale or in batch type production various components go into assemblies. These are inspected on audit or 100% basis. The functional gauges fulfill such requirement taking into consideration size and shape of the component along with center distances between holes.

PMS has manufactured wide range of gauges of some which are described below.

| Gauge for Automobile Door - |

|

|

|

|

This gauge is manufactured for an automobile door. It checks 2 parameters; the fitment and the required gap between car body and door. With the help of 3D models; various sections are manufactured and fitted in the respective position to ensure the shape of the door. A pin of specific size rolled inside the door to ensure uniform gap. |

|

| Oil Hole Checking Gauge for Crank Case - |

|

|

|

|

We have catered relation gauges for cylinder block and crankcase of renowned motorbike. These gauges are used for checking parameters like chain dispenser flange, notch, stud holes, breather hole, oil hole and height. |

|

| Relation Gauge for Main Bearing Cap - |

|

|

|

|

This is a relation checking gauge designed and manufactured for main bearing cap of a diesel engine. The main purpose of this gauge is to check whether the component is within specified tolerances as well as to find if there exists any missing operation. |

|

| |

|

|

|

|